Why Acrylic Adhesive Tapes Are Replacing Traditional Solutions?

Oct 16, 2025

If you've worked in manufacturing or packaging for a while, you've probably noticed how fast acrylic adhesive tapes are showing up on production lines. Five or ten years ago, most factories still relied on screws, welding, or liquid glue. Now, more buyers - especially from growing markets like Brazil - are moving toward acrylic tapes because they solve problems that traditional methods couldn't.

Acrylic Tapes: A Practical Upgrade, Not Just a Trend

The biggest reason behind this shift is performance in real working conditions. Acrylic adhesives stay strong even when exposed to heat, moisture, and sunlight. A typical high-grade acrylic tape can handle temperatures of around 120–150°C and still keep a firm bond.

For factories that deal with outdoor parts, metal bonding, or long-term storage, this reliability is hard to beat.

Acrylic tapes also stick to a wider range of materials - from smooth aluminum to textured plastics - making them a flexible choice when production involves multiple substrates.

What They Replace (and Why It Matters)

Let's be honest - drilling holes or waiting for glue to cure slows production down. Acrylic tapes eliminate that.

They create instant, even bonds without adding extra steps. The surface looks cleaner, and the overall assembly is lighter because you remove unnecessary hardware.

In one of our partner factories that switched from rivets to tape for metal nameplates, the assembly speed increased by almost 25%, and the defect rate dropped noticeably. No need for drying rooms or constant surface finishing - just apply and move on.

Where You'll Find Them Now

Acrylic tapes are showing up everywhere:

Automotive: attaching trims, emblems, and sensors.

Electronics: securing screens, batteries, and small parts.

Construction: mounting glass panels or insulation boards.

Heavy packaging: sealing reinforced cartons or foam inserts.

Global research groups estimate that acrylic-based tapes now account for more than 40% of industrial bonding applications, and that share is still growing.

A Cleaner and Greener Option

Factories today don't just look at cost - they care about safety and emissions. Acrylic tapes require no heating, mixing, or curing chemicals, which cuts down VOC emissions and energy consumption. Many manufacturers (including us) are now offering water-based acrylic formulations, helping customers meet environmental compliance goals without extra investment.

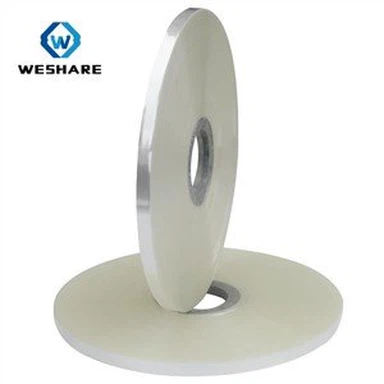

How Weshare Fits In

At Weshare, we don't just resell generic tapes. We develop our own acrylic adhesive systems that balance tack strength, peel resistance, and durability for different environments.

We supply to manufacturers that build everything from small electrical components to structural metal panels. Our team helps customers test adhesion on their specific materials, adjust thickness, and customize roll sizes for automated lines.

Because we produce in-house and hold ISO certifications, clients know that what they receive is consistent batch after batch. That reliability is what long-term buyers appreciate most.

Final Takeaway

Acrylic adhesive tapes are quietly transforming how things are built - faster, cleaner, and with less waste. The companies adopting them early are cutting labor hours and improving product finish at the same time.

If your business is looking to upgrade from screws or glue, or simply needs a more stable adhesive partner, Weshare is here to help.

We've seen firsthand how the right tape can simplify production - and we're ready to show you what it can do for yours.